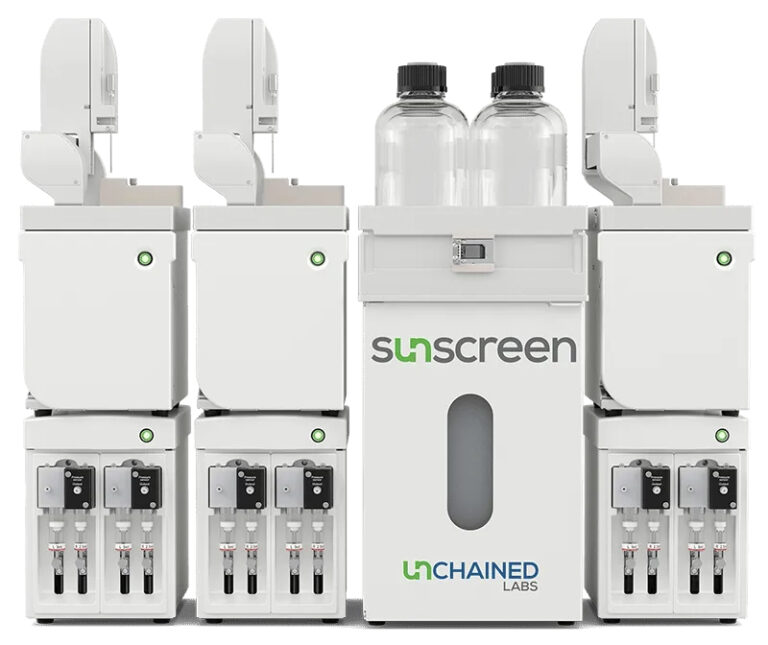

Sunscreen

- Capabilities

- Specifications

- Crank them out

- Finding the perfect LNP formulation can feel like it drags on forever.

- You need to figure out the best lipid mixture, the right lipid to payload ratio and the optimal flow rates to mix it all together.

- Worst of all, it’s usually done one experiment at a time. Sunscreen totally flips the script by creating 96 unique, small volume LNP formulations in less than 6 hours – so you can explore more formulations in a single day than you ever thought was possible.

- 96 formulations in <6 hours

- 200 μL – 2 mL per experiment

- 0.1 – 30 mL/min flow rates

- Reusable microfluidics

- Scalable method

- Mix it up

Fill one plate with payloads, the other with lipids and you’re ready to mix them up with a Sunny. For a simple, well-known T-mixing approach grab a Sunny T, or to increase fluid contact area for particle formation with a cross-junction, use a Sunny X. To use Sunscreen’s full range of flow rates, ratios and integrated in-line dilution, choose a Sunny Trident. Sunnies can easily be subbed in and out of Sunscreen so once you find your favorite, you can use it over and over again.

- Set it, forget it

Tell Sunscreen’s Sunny Suite Software what’s in your plates, the lipid to payload ratios, the flow rates you want to mix at, and you’re ready to go. The software checks to make sure your experiments will work, so you don’t need to worry about screwing things up. Sunscreen takes it from there, knocking out an entire plate of LNPs way before the day is done. You’ll still have you plenty of time to start buffer exchange or characterization – all before you clock out.

- Bank on it

When you ask Sunscreen to make a full plate of formulations, you can trust that everyone will be made consistently, with no variability across the entire plate. The automated washing protocol between experiments ensures that nothing carries over from the last formulation, so a not-so-good formulation won’t affect the next good one. If you really want to supercharge your workflow, grab a Stunner to check the LNP sizes and PDIs in less than an hour to suss out your winners right away.

- Narrow it down

Once you’ve found a great lipid mix, Sunscreen helps you take the first pass at finding the right ratios and flow rates to get the size just right. When you’re ready to scale up the killer conditions you find on Sunscreen, they can be transferred directly to Sunshine and on to Sunbather – the Sunny too.

- Do more with less

mRNA, siDNA and pDNA typically cost a ton and are difficult to make. Sunscreen lets you use way less of these precious payloads each time you try to get them into LNPs. Scale down your experiments and save lots of dough while you figure out your formulation.

- The Sunny Suite

The Sunny Suite has a killer solution for every step of your LNP development. Sunscreen automates high-throughput screening of up to 96 formulations at a time to help you quickly discover your winning LNP formulations. Sunshine then takes your best formulations and hones in on the perfect mixing process conditions, with both automated experiments and continuous flow modes. When you’re ready for clinical trials, Sunbather dials up your particles in a fully GMP-compliant environment.

- Trust the process

Using the same pumps for fluid delivery, and same range of Sunnies for mixing up your formulations, the Sunny Suite makes the transition from formulation screening to process development to GMP production smooth sailing. Whether you’re screening through hundreds of 200 μL formulations or producing liters of particles for clinical trials, you can trust the Sunny Suite to deliver the same consistent results at any scale.

Application | |

| Throughput | Up to 96 formulations within 6 hours |

| Total flow rate range | 0.1–30 mL/min (chip dependent) |

| Flow rate ratio (aqueous to organic) range | 1:1 to 5:1 |

| Typical sample volume range (at a 3:1 FRR) | 400 µL–2 mL |

| Minimum input volume (including dead volume) | 105 µL |

| Continuous mode volume range | NA |

| In-line dilution | Yes |

| Typical particle size range | 40–200 nm* |

| PDI | <0.2* |

| Encapsulation efficiency | >90%* |

Instrument | |

Physical | |

| Weight and dimensions (required space) | 57 kg, 60 cm H x 90 cm W x 40 cm D |

| Operating pressure | 0-10 bar |

Electrical | |

| Voltage input | 100 V–240 V AC, 50-60 Hz |

| Communications | USB via Sunny Suite Software |

Other Information | |

| Fluidic port sizes | ¼”-28 and 10–32 and Luer fittings |

| Sample loop size | 2.5 mL |

| Fluid store volumes | 4 x 1000 mL bottles |

| Waste storage volume | 5 L |

| Wetted materials | PTFE, PCTFE, FEP, ETFE, PEEK, Polypropylene, FFKM, Hastelloy C276, Stainless Steel T316, Glass, Tygon (Waste Tubes), HDPE (Waste Container) |

| Computer | Separate computer with Win 11, monitor, keyboard and mouse |

Consumable | |

| Sunnies | Glass microfluidic mixing devices of various geometries and channel sizes |

| Available types | Sunny 490 Trident T, Sunny 100 X, Sunny 100 T, Sunny 190 X, Sunny 190 T, Sunny 275 X,Sunny 275 T, Sunny 150 3D, Sunny 50 Micromixer |

Overview

The primo LNP formulation screener

Capabilities

- Crank them out

- Finding the perfect LNP formulation can feel like it drags on forever.

- You need to figure out the best lipid mixture, the right lipid to payload ratio and the optimal flow rates to mix it all together.

- Worst of all, it’s usually done one experiment at a time. Sunscreen totally flips the script by creating 96 unique, small volume LNP formulations in less than 6 hours – so you can explore more formulations in a single day than you ever thought was possible.

- 96 formulations in <6 hours

- 200 μL – 2 mL per experiment

- 0.1 – 30 mL/min flow rates

- Reusable microfluidics

- Scalable method

- Mix it up

Fill one plate with payloads, the other with lipids and you’re ready to mix them up with a Sunny. For a simple, well-known T-mixing approach grab a Sunny T, or to increase fluid contact area for particle formation with a cross-junction, use a Sunny X. To use Sunscreen’s full range of flow rates, ratios and integrated in-line dilution, choose a Sunny Trident. Sunnies can easily be subbed in and out of Sunscreen so once you find your favorite, you can use it over and over again.

- Set it, forget it

Tell Sunscreen’s Sunny Suite Software what’s in your plates, the lipid to payload ratios, the flow rates you want to mix at, and you’re ready to go. The software checks to make sure your experiments will work, so you don’t need to worry about screwing things up. Sunscreen takes it from there, knocking out an entire plate of LNPs way before the day is done. You’ll still have you plenty of time to start buffer exchange or characterization – all before you clock out.

- Bank on it

When you ask Sunscreen to make a full plate of formulations, you can trust that everyone will be made consistently, with no variability across the entire plate. The automated washing protocol between experiments ensures that nothing carries over from the last formulation, so a not-so-good formulation won’t affect the next good one. If you really want to supercharge your workflow, grab a Stunner to check the LNP sizes and PDIs in less than an hour to suss out your winners right away.

- Narrow it down

Once you’ve found a great lipid mix, Sunscreen helps you take the first pass at finding the right ratios and flow rates to get the size just right. When you’re ready to scale up the killer conditions you find on Sunscreen, they can be transferred directly to Sunshine and on to Sunbather – the Sunny too.

- Do more with less

mRNA, siDNA and pDNA typically cost a ton and are difficult to make. Sunscreen lets you use way less of these precious payloads each time you try to get them into LNPs. Scale down your experiments and save lots of dough while you figure out your formulation.

- The Sunny Suite

The Sunny Suite has a killer solution for every step of your LNP development. Sunscreen automates high-throughput screening of up to 96 formulations at a time to help you quickly discover your winning LNP formulations. Sunshine then takes your best formulations and hones in on the perfect mixing process conditions, with both automated experiments and continuous flow modes. When you’re ready for clinical trials, Sunbather dials up your particles in a fully GMP-compliant environment.

- Trust the process

Using the same pumps for fluid delivery, and same range of Sunnies for mixing up your formulations, the Sunny Suite makes the transition from formulation screening to process development to GMP production smooth sailing. Whether you’re screening through hundreds of 200 μL formulations or producing liters of particles for clinical trials, you can trust the Sunny Suite to deliver the same consistent results at any scale.

Specifications

Application | |

| Throughput | Up to 96 formulations within 6 hours |

| Total flow rate range | 0.1–30 mL/min (chip dependent) |

| Flow rate ratio (aqueous to organic) range | 1:1 to 5:1 |

| Typical sample volume range (at a 3:1 FRR) | 400 µL–2 mL |

| Minimum input volume (including dead volume) | 105 µL |

| Continuous mode volume range | NA |

| In-line dilution | Yes |

| Typical particle size range | 40–200 nm* |

| PDI | <0.2* |

| Encapsulation efficiency | >90%* |

Instrument | |

Physical | |

| Weight and dimensions (required space) | 57 kg, 60 cm H x 90 cm W x 40 cm D |

| Operating pressure | 0-10 bar |

Electrical | |

| Voltage input | 100 V–240 V AC, 50-60 Hz |

| Communications | USB via Sunny Suite Software |

Other Information | |

| Fluidic port sizes | ¼”-28 and 10–32 and Luer fittings |

| Sample loop size | 2.5 mL |

| Fluid store volumes | 4 x 1000 mL bottles |

| Waste storage volume | 5 L |

| Wetted materials | PTFE, PCTFE, FEP, ETFE, PEEK, Polypropylene, FFKM, Hastelloy C276, Stainless Steel T316, Glass, Tygon (Waste Tubes), HDPE (Waste Container) |

| Computer | Separate computer with Win 11, monitor, keyboard and mouse |

Consumable | |

| Sunnies | Glass microfluidic mixing devices of various geometries and channel sizes |

| Available types | Sunny 490 Trident T, Sunny 100 X, Sunny 100 T, Sunny 190 X, Sunny 190 T, Sunny 275 X,Sunny 275 T, Sunny 150 3D, Sunny 50 Micromixer |